Water jet cutting with pure water is mainly suitable for cutting soft materials such as food foams papers or plastics.

Water jet cutting technology ppt.

While early waterjets could easily cut soft materials they were not effective in cutting harder materials.

Using water as a cutting method for soft materials has been around for decades.

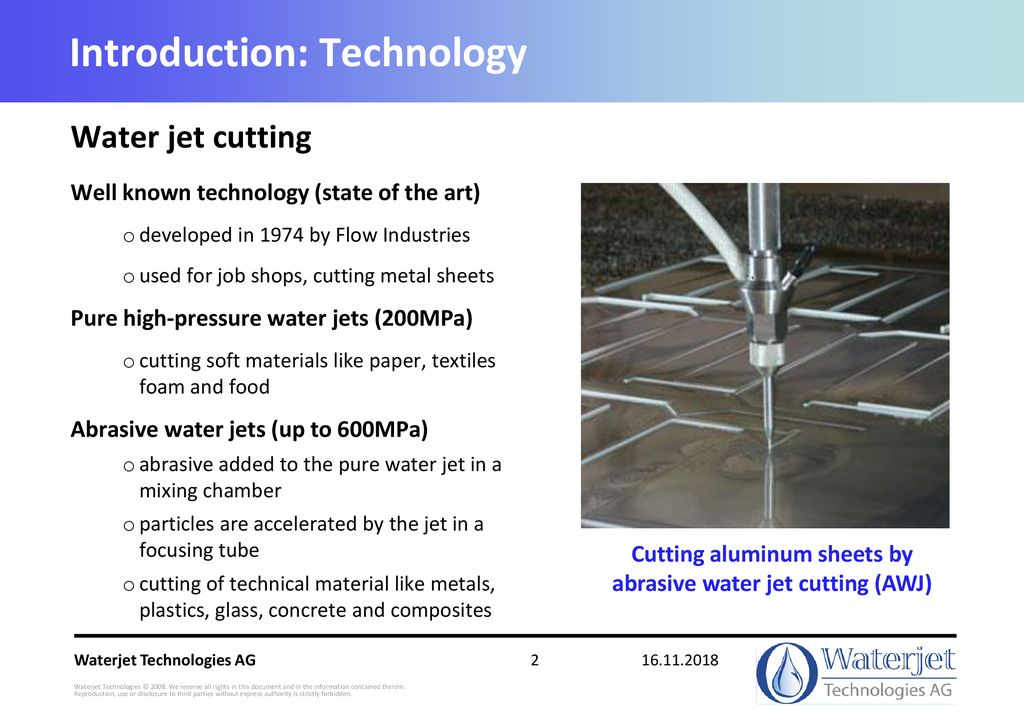

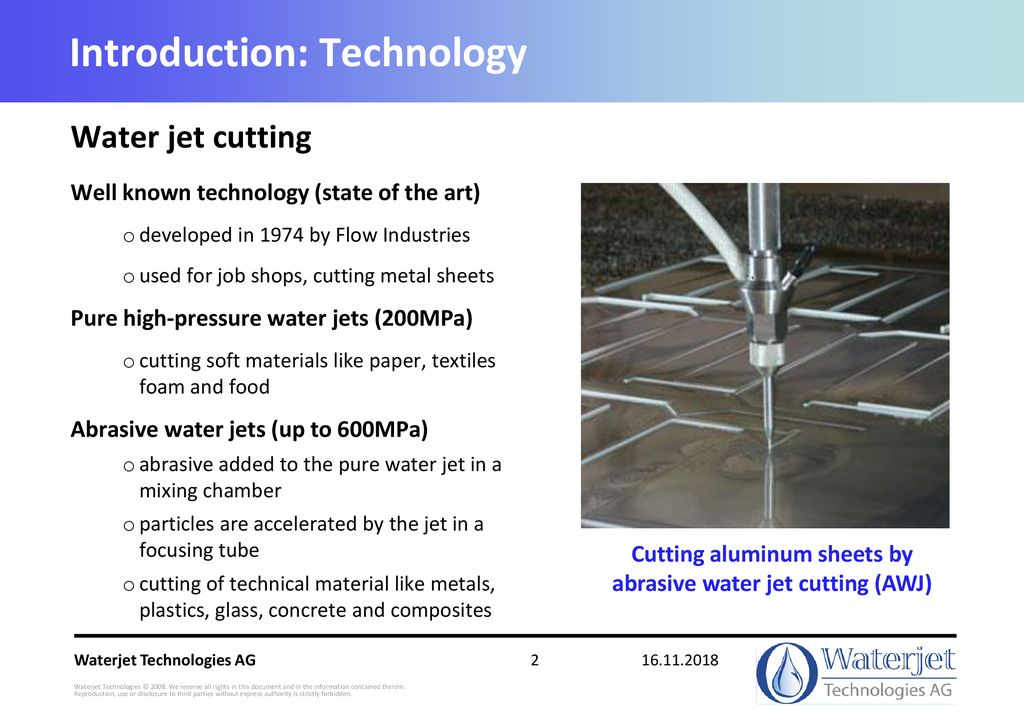

A water jet cutter also known as a water jet or waterjet is an industrial tool capable of cutting a wide variety of materials using a very high pressure jet of water or a mixture of water and an abrasive substance.

Water jet cutting if the cutting edge quality of flame cutting fulfills the requirements then flame cutting is more cost effective than water jet cutting.

Water jet cutting provides benefits with respect to the surface because depending on the process there are no weld spatters and no burr formation.

In the food sector for example it is used for cutting cheese fruit or vegetables.

Introduction to waterjet it is an industrial tool capable of cutting a.

Early forms such as the paper metering system by the paper patents company in the 1930s used relatively low pressure water.

Introduction to water jet br it is a tool capable of slicing metal or other materials using a jet of water at high velocity and pressure br the process is same as water erosion found in nature but is greatly accelerated and concentrated br true cold cutting process.

Plastic materials to be separated can be foils and seals.

Kishan kumar singh mechanical engg.

Two types of cutting let us take a closer look at the basics of the two waterjet cutting methods.

Pure water cutting pure waterjet is used mainly for relatively soft materials such as plastic textiles paper sealing materials metalic foils.

3rd year overview introduction types of water jet cutters advantage disadvantage future of water jet cutter conclusion.

Also explore the seminar topics paper on waterjet cutting with abstract or synopsis documentation on advantages and disadvantages base paper presentation slides for ieee final year mechanical engineering me or production automobile students for the year 2019 2020.

Water jet cutting a technology on the rise october 2010 page 7 5.

Waterjet technology is a cold cutting process which cuts by using supersonic water or water and abrasive to erode material.

Water and garnet exit the cutting head at nearly four times the speed of sound capable of cutting steel over one foot thick.

Water jet cutting technology br ankit pal br me 5th sem br 0902940012 br 2.

The term abrasive jet refers specifically to the use of a mixture of water and abrasive to cut hard materials such as metal or granite while the terms pure waterjet and water.

Other materials are carpets textiles fibrous materials or insulating materials.

The part can also be processed further.

Wide variety of materials using a very highpressure jet of water.

Because of this waterjets are unlimited in what they can cut.

Pure abrasive waterjet.